Air Leak Testing

Air leak testing solutions are designed to verify the integrity, sealing performance, and leak tightness of components and assemblies used in automotive, aerospace, HVAC, fluid handling, and industrial applications. These systems ensure that products meet stringent quality standards by detecting leaks that could compromise performance, safety, or reliability.

Teemer Tech provides turnkey automated air leak testing solutions by integrating precision leak testing instruments with industrial robots, conveyors, and material handling systems.

Air leak testing cells enable:

• Automated loading, clamping, and sealing of parts

• Accurate detection of micro-leaks in housings, valves, pipes, and welded assemblies

• Inline or end-of-line testing with high repeatability

• Part handling and segregation of OK / NOK components

• Data logging, traceability, and SPC for quality compliance

These systems eliminate manual testing variability, reduce cycle time, and prevent quality bottlenecks while ensuring 100% inspection capability. Teemer Tech air leak testing solutions are scalable, flexible, and fully compatible with Industry 4.0 and IoT-enabled manufacturing environments.

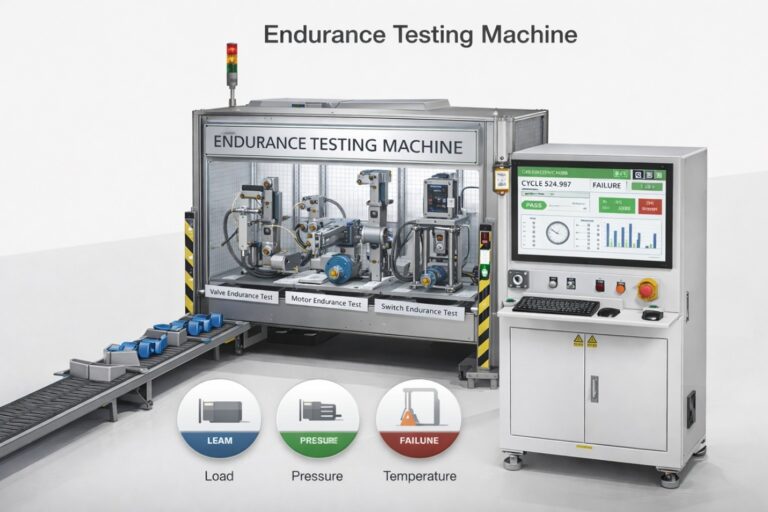

Endurance Testing

• Programmable cyclic testing for load, pressure, torque, motion, or temperature

• High-accuracy monitoring of force, displacement, pressure, flow, and cycle count

• Continuous operation for high-cycle life testing

• Automatic pass/fail detection and failure alerts • Data logging, trend analysis, and report generation

• Integration with PLC, HMI, SCADA, and Industry 4.0 systems These machines reduce manual intervention, improve test repeatability, and ensure compliance with OEM, ISO, and customer-specific standards. Teemer Tech endurance testing solutions are engineered for robustness, safety, and scalability, making them ideal for R&D labs, validation centers, and production environments.