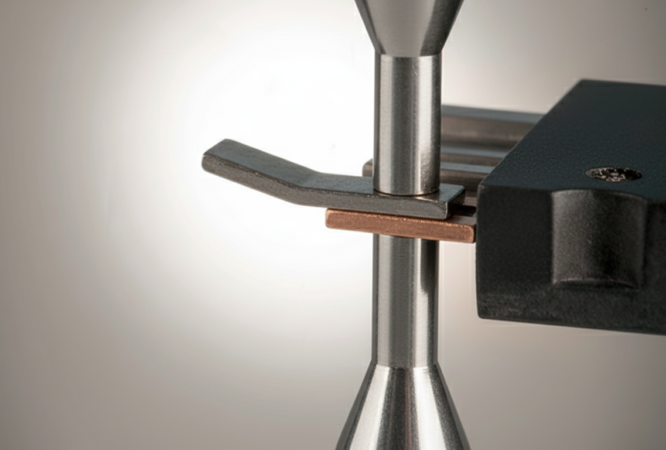

Resistance welding is a metal joining process in which heat is generated by the electrical resistance of the materials being joined when an electric current passes through them. The heat, combined with applied pressure, causes the metal surfaces to fuse together without the use of filler material.

This welding process is widely used in mass production due to its high speed, repeatability, energy efficiency, and ease of automation. Resistance welding is commonly applied to sheet metals, especially in the automotive, appliance, electronics, and battery manufacturing industries.

Advantages of Resistance Welding

• High production speed

• Consistent weld quality

• No filler metals or flux required

• Minimal distortion and clean welds

• Easily automated for mass manufacturing

Key Types of Resistance Welding

• Spot Welding: Joins overlapping sheets at specific points

• Seam Welding: Creates continuous welds using rotating electrodes

• Projection Welding: Uses raised projections for precise, multiple welds

• Flash & Upset Welding: Ideal for rods, bars, rails, and structural parts

• Butt Welding: End-to-end joining of wires and tubes