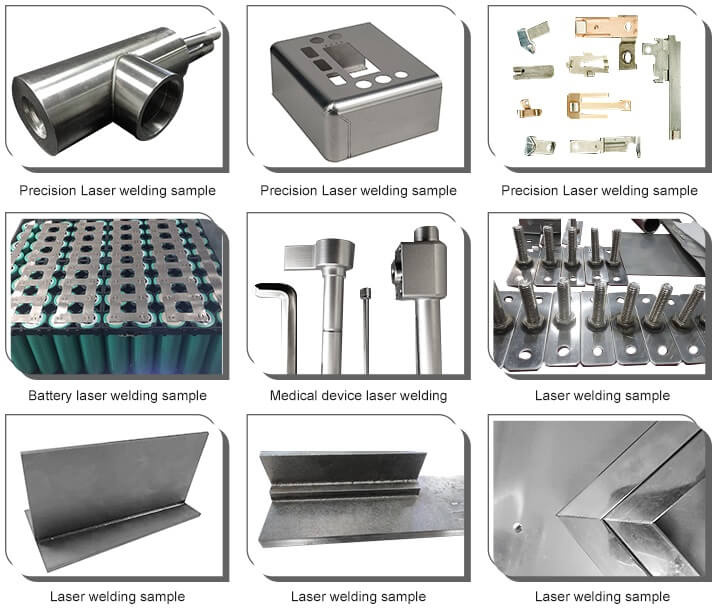

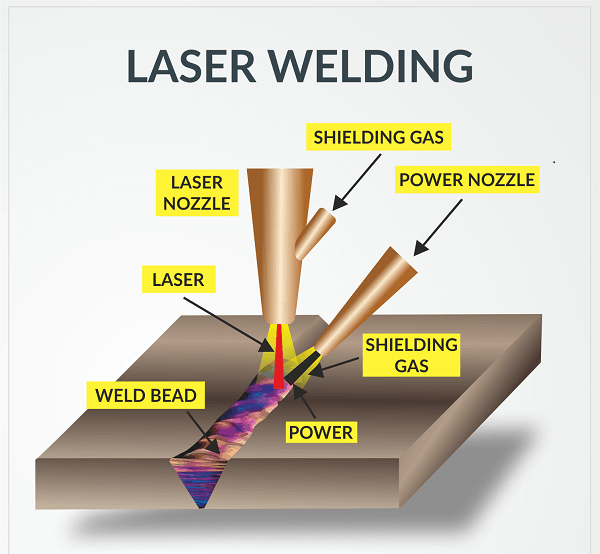

This type of welding is suitable for applications that require high speeds and for welding both thick and thin metals with minimal thermal distortion. The high speed of the process, combined with the ability to control weld quality during operation and its high level of automation, makes laser welding a widely used method across many industrial sectors such as electronics, tool making, battery assembly, electric vehicles, and the automotive industry.

High-Precision Laser Welding Machines - Speed, Strength, and Minimal Distortion

Revolutionize Your Fabrication with State-of-the-Art Welding Technology

Why Choose Laser Welding Machines for Mass Manufacturing?

Laser welding machines are in high demand for mass manufacturing of industrial components because they offer several advantages over other joining technologies currently in use. The major advantages include:

• Precision and Accuracy: Suitable for intricate designs and small components.

• High Speed and Productivity: Reduces welding time compared to conventional methods.

• Minimal Heat-Affected Zone (HAZ): Preserves material properties and reduces distortion.

• Versatility: Works with a wide range of materials, including metals, plastics, and dissimilar materials.

• Automation-Friendly: Easily integrates into robotic and automated manufacturing systems.

• Clean and Contactless: Reduces contamination and eliminates the need for filler materials.