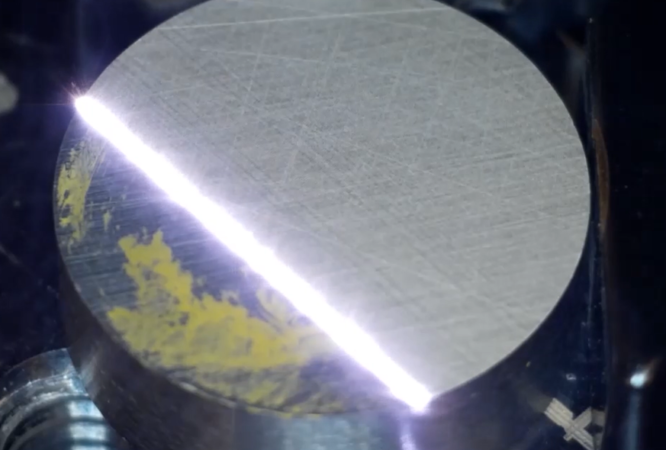

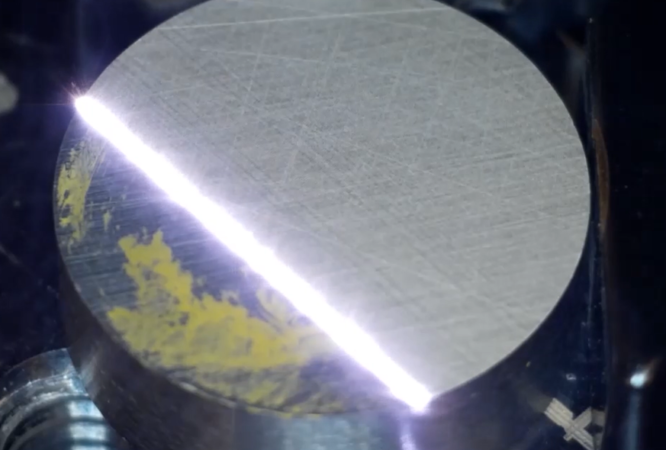

Laser cleaning, also known as laser ablation, is an advanced and environmentally friendly process used to remove rust, paint, oil, grease, oxides, and surface contaminants from metal surfaces—without causing any damage to the base material.

Thanks to its precision, efficiency, and non-abrasive nature, laser cleaning is increasingly used across industries for applications such as automotive components, battery terminals, monuments, molds, aircraft parts, weapons, and industrial tools.

Why Choose Laser Cleaning?

Laser cleaning offers several advantages over traditional industrial cleaning methods:

• Non-Contact & Damage-Free: Cleans surfaces without abrasion or substrate damage

• Eco-Friendly Process: No chemicals, no consumables, and no secondary waste

• High Speed & Efficiency: Faster cleaning with minimal downtime

• Dry Cleaning Technology: Eliminates the need for water or chemicals

• Remote Operation Capability: Ideal for hard-to-reach or hazardous areas

A Smarter Alternative to Traditional Cleaning

Conventional cleaning methods such as sandblasting, dry ice blasting, or chemical treatments are often time-consuming, labor-intensive, and environmentally hazardous. Chemical oxide removal requires material-specific treatments, while abrasive blasting methods can damage the underlying metal surface.

Laser cleaning systems provide a superior alternative—energy-efficient, precise, and significantly faster, delivering consistent results without compromising surface integrity.

Laser cleaning is highly effective in both pre-weld and post-weld processes:

• Before Welding: Removes contaminants to ensure cleaner surfaces, resulting in stronger and more reliable weld joints

• After Welding: Eliminates burn marks and discoloration, improving surface finish and overall quality

Laser cleaning technology delivers precision, sustainability, and performance, making it the ideal solution for modern industrial cleaning challenges.