Robotic welding inspection – Quality and measuring solution

Robotic welding inspection solutions are designed to ensure consistent weld quality, dimensional accuracy, and process reliability across high-volume and high-precision manufacturing environments. By combining industrial robots with advanced inspection and measurement technologies, these systems automate post-weld and in-process quality checks while eliminating human variability.

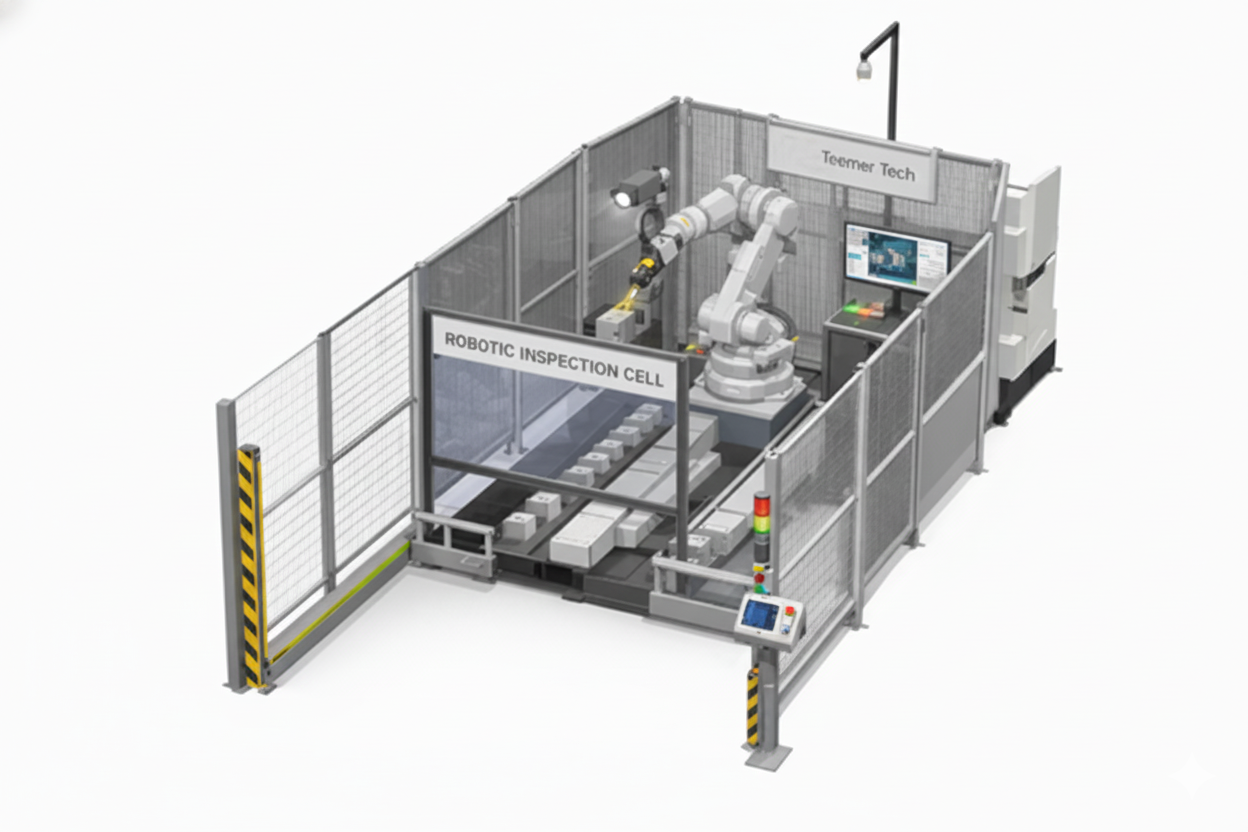

Teemer Tech provides turnkey robotic welding inspection solutions using vision-based inspection systems, laser scanners, seam tracking sensors, and metrology devices, including integration with Coordinate Measuring Machines (CMMs).

Collaborative and industrial robots are deployed to inspect weld beads, joint geometry, penetration depth, surface defects, and dimensional tolerances.

Our robotic inspection cells can:

• Inspect weld seams for porosity, cracks, undercut, overlap, and misalignment

• Measure weld bead width, height, profile, and positional accuracy

• Perform non-contact laser and 3D vision-based inspections

• Handle parts and present them to stationary inspection systems or CMMs

• Manipulate inspection tools such as scanners, probes, cameras, and sensors.

By automating welding inspection, manufacturers can eliminate inspection bottlenecks, improve throughput, ensure traceability, and achieve repeatable, objective quality control. Robotic welding inspection also supports data logging, SPC, and Industry 4.0 integration, enabling continuous process improvement and compliance with quality standards.

• Inspect weld seams for porosity, cracks, undercut, overlap, and misalignment

• Measure weld bead width, height, profile, and positional accuracy

• Perform non-contact laser and 3D vision-based inspections

• Handle parts and present them to stationary inspection systems or CMMs

• Manipulate inspection tools such as scanners, probes, cameras, and sensors.

By automating welding inspection, manufacturers can eliminate inspection bottlenecks, improve throughput, ensure traceability, and achieve repeatable, objective quality control. Robotic welding inspection also supports data logging, SPC, and Industry 4.0 integration, enabling continuous process improvement and compliance with quality standards.

Robotic vision inspection – Solution with Vision cameras

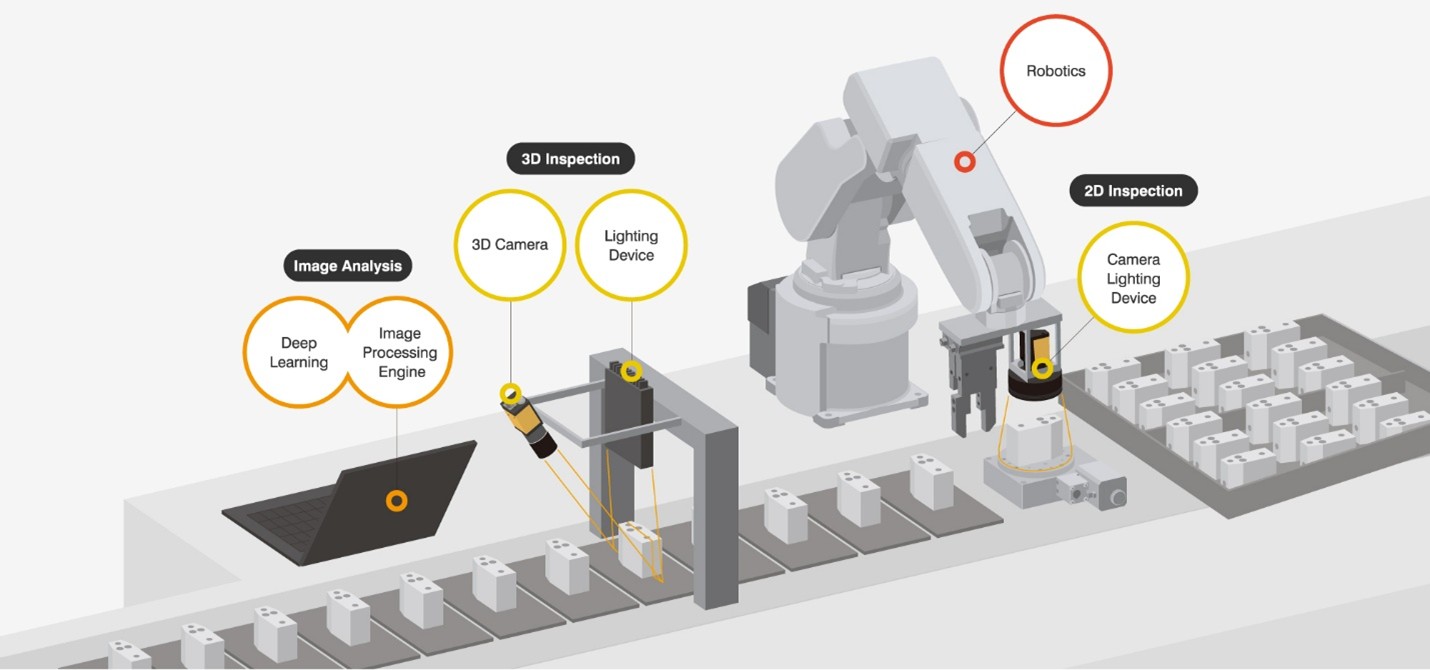

Inspection robots are mobile or stationary service robots equipped with advanced vision and sensing technologies, designed for the inspection of critical and high-value components and infrastructure. These systems can be semi-autonomous, following pre-taught paths, or fully autonomous, capable of self-navigation and adaptive inspection.

Teemer Tech provides end-to-end robotic inspection solutions using vision-based systems and by integrating robots with Coordinate Measuring Machines (CMMs). Collaborative robots (cobots) are widely deployed for inspection tasks, offering flexibility, safety, and ease of integration within existing production environments.

In many manufacturing facilities, inspection processes can become a production bottleneck. Robotic inspection work cells eliminate these constraints by ensuring consistent, accurate, and high-speed quality checks, allowing upstream and downstream operations to run at full capacity.Our inspection solutions enable robots to:

• Handle and position work pieces for stationary inspection systems

• Present parts directly to operators for assisted visual inspection

• Manipulate inspection devices such as vision sensors, probes, scanners, and metrology measuring heads

By automating inspection processes, Teemer Tech helps manufacturers improve quality, throughput, and repeatability while reducing dependency on manual inspection.