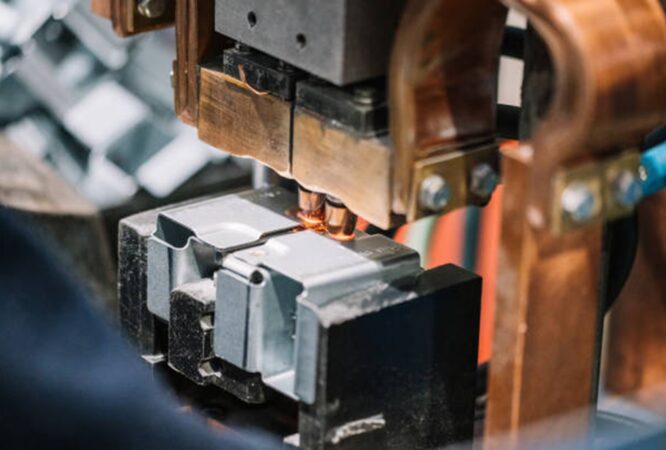

Resistance / Spot Welding Solution

We provide high-performance resistance and spot welding solutions designed for battery manufacturing, automotive components, and precision sensor assembly, delivering consistent weld quality at industrial scale. Our systems are engineered for seamless integration into automated production lines, aligning with existing conveyor layouts, takt times, and process flows. By combining advanced welding power supplies, precision fixturing, force control, and real-time weld monitoring, helping manufacturers achieve repeatable quality, high throughput, and reduced rework

• Battery cell interconnections and module assembly

• Automotive body and structural components

• Busbars, terminals, and sheet-metal parts

• Electronic and automotive sensor welding

• Copper, aluminum, nickel, and dissimilar metal joints

Our modular, scalable platforms are suitable for R&D labs, pilot lines, series production, and high-volume manufacturing, enabling customers to scale confidently as demand grows.

• Consistent, high-strength welds across materials

• Optimized cycle times for mass production

• Integrated process and quality monitoring

• Low maintenance and high system uptime

• Flexible solutions for multiple industries and use cases

Positioned at the intersection of advanced manufacturing, electrification, and automation, Teemer Tech’s resistance and spot welding technologies empower manufacturers to build reliable, cost-effective, and future-ready production lines.

Robotic Welding

Teemer Tech Pvt. Ltd. delivers comprehensive robotic automation solutions across a wide spectrum of industrial applications, with welding being one of the most widely deployed and value-critical processes.

We provide turnkey Robotic Arc Welding and Robotic Spot Welding solutions to customers across automotive, EV, battery, heavy engineering, and general manufacturing industries—enabling higher productivity, consistent weld quality, and scalable operations.

• Sophisticated mechanical fixtures and tooling

• Turntables and work piece positioners

• Swivel tool changers

• Integrated safety systems

• IoT-enabled control and monitoring systems

In arc welding, base metals are fused using the heat generated by an electric arc formed between the electrode and the work piece. In spot welding, materials are joined by passing a high electric current through the base metals, generating heat due to electrical resistance at the joint interface.

Robotic welding systems significantly outperform manual welding, delivering three to five times higher productivity through continuous operation, increased arc-on time, precise motion control, and rapid movement between weld joints. This results in reduced cycle times, improved repeatability, and enhanced operator safety.

We possess strong expertise in Robotic Aluminum Welding and Robotic Stainless-Steel Welding, where precision, thermal control, and process stability are critical to product quality.

Identifying the right robotic welding system determines the optimal welding process for each application. Teemer Tech offers turnkey robotic welding solutions across a broad range of technologies, including:

• Resistance Spot Welding

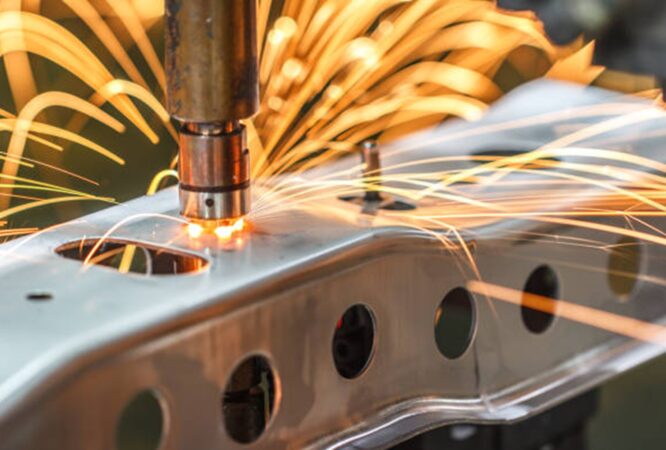

• Laser Welding

• Gas Metal Arc Welding (GMAW / MIG)

• Gas Tungsten Arc Welding (GTAW / TIG)

• Plasma Welding

• Laser Hybrid Welding

By combining robotics, advanced welding processes, intelligent automation, and digital monitoring, Teemer Tech enables manufacturers to achieve higher throughput, superior weld integrity, and future-ready production lines.